Dave steers Doolittle mid Atlantic. Note his burgundy jacket, later changed for a beige one to keep him dry and cool.

Over the last couple of decades I have had a love hate relationship with autopilots. My last boat was a long keeled classic with a steep angle on the rudder and this caused no end of problems and over the years I tried and consequently destroyed most of the autopilots on the market.

By the time I had bought the Dana 24 I had ruined no less than 10 pilots and not one of them worked very well. When it came to buying an autopilot for ‘Doolittle’ I thought long and hard about buying an under deck unit but the way the Dana rudder is would have meant serious structural changes would have needed to be made. Then there’s the fact that under deck pilots are very complicated and consume a lot of power.

In the end it just didn’t seem worth it and besides, maybe the Dana with it’s vertical rudder and more modern shape would allow a modest tiller pilot to work. After a terrible experience with Autohelm (now Ratheon) I vowed I would never have anything to do with that company again so I went with the Simrad TP30.

Most autopilots make outrageous claims about the size of boat they can be used on. The TP30 is rated for boats up to 42 feet long so I figured that it should be about right for a 24 foot boat. Maybe if you are just using it in gentle conditions or motoring these claims are correct but I can’t imagine the TP30 steering a 42 foot yacht sailing in rough conditions.

Whether a tiller pilot works well on your boat will depend on how easy it is to steer when you are on the helm. If you have to put a lot of pressure or input in when sailing then the tillerpilot will struggle. If on the other hand, the boat is light on the helm and easy to steer (like most modern boats) the chances of an tillerpilot working are much greater.

On my last boat, the only way the pilot would hold a course was to set it up on it’s maximum gain (the speed of response to course change) and minimum sea state. The only trouble with this was that the tillerpilot was working like mad the whole time and this in itself caused problems. For some reason electronics manufacturers love to make everything black. I don’t know why they do this but when you are sailing in the Med in the summer, temperatures can get very high indeed. With a black horizontal surface soaking up the heat of the midday sun and the pilot working overtime, the pilot gets ridiculously hot. In fact one time in Sicily it got so hot that the cog spun on the motor shaft and rendered the pilot useless.

Suffice to say, I learned a lot about steering and tillerpilots over the years. The other thing I discovered is that the worst thing you can do, apart from using a tiller pilot on a classic yacht is to let them get wet. They don’t like it!

If you want your pilot to last the secret is this. Adjust it so it doesn’t work very much when steering the boat. By that I mean, do not load it up with excessive weather helm. If you are sailing you should reef the main very early so as not to load up the helm. Adjust the settings so that the boat can swing about a bit before the pilot starts steering. Don’t let it get wet or hot. I know that this is asking a lot but if you ignore this advice you will have all sorts of problems.

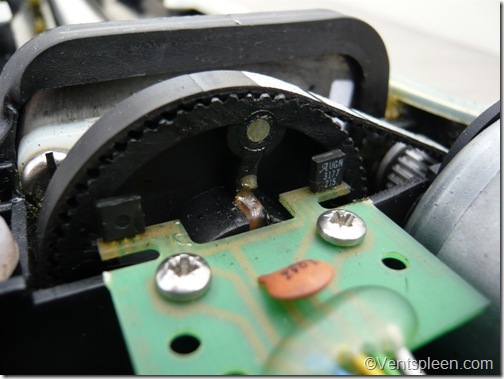

Pic shows the cog wheels. Two magnetic pins are pressed into the larger cog. If they slip out, they will smash the Hall sensors on the PCB.

The unit itself is mostly made of plastic and frankly isn’t very tough and there a few design faults which can render the pilot useless. The biggest problem are the magnetic pins in the larger cog wheel. These tell the pilot where the arm is and without them simply will not work. What normally happens is this: The magnetic pins start to work themselves out and then they smash into the delicate Hall sensors which are fitted to a small PCB. When that happens the pilot won’t work. It would be wise to always carry a spare PCB with the Hall sensors on it. It is easy to replace and very likely to get damaged sooner or later.

Another problem that you may experience is the slipping of the motor cog which is only pressed onto the motor shaft. Most of the time this cheap way of attaching the cog is sufficient but if the tillerpilot gets hot and is working hard it may very well start to slip and then the pilot will not work.

If you do buy a TP30 or the latest TP32 (which I assume is pretty much the same design inside) get used to the idea that you will have to take it apart on a regular basis. They claim that all you need to do is smear a bit of silicone grease on the shaft every now and then but this won’t be enough.

There are ten cross head screws in the underside of the pilot, unscrew them all and open the pilot like a book. (see pic). There is no need to dismantle the unit any more than this. The motor simply lifts out for easy access to it’s ends.

The most important thing you must do is push the magnetic pins out and glue them in properly with superglue. If you don’t do this, then one day the pins will ease out and smash the Hall sensors.

If you hear your pilot squeaking during use I recommend taking it apart and putting a drop of machine oil at either end of the motor itself. While the unit is apart put more grease on the worm drive and replace the belt if it is not tight. There is no tension device on the belt so if it is stretched it may slip.

You can take the panel off the electric part of the tiller pilot but this seems quite well sealed and in any case if the electrics do fail, there won’t be a lot you can do anyway so I suggest you leave it alone!

You can buy a spares kit which includes a new seal but I have found that if you don’t try to remove the seal when you open the unit it lasts for many years. In fact fitting a new seal is quite tricky so best not to touch it at all unless it is obviously broken.

To stop the tillerpilot over heating in the sun and to reduce the chance of water getting in make a jacket for it using a pale coloured material. Since our tillerpilot (Dave) has had a jacket he has been much more reliable. This is probably the most important thing you can do to keep your pilot working for as long as possible.

If you are having problems with the pilot suspect the electrical connections. If the pilot doesn’t get a good solid voltage it will cut out and behave erratically. Always check the socket, wiring and plug first before doing anything else.

So that covers the problems you are likely to have and how to avoid some of them. Let’s discuss the pilot itself.

At this point I have to say that we have had Dave on Doolittle for 6 years now and he has steered the boat across the Atlantic and has now done about 13,000 miles. This is most impressive for a plastic tillerpilot but there is no way he would have done this if not for his jacket and the regular oiling and greasing of his innards. He has had a new belt installed but apart from that he is original. The shaft is a bit pitted and corroded where some salt water has got in at some point but so far (touch wood) he is still working.

I think this says more about the Dana 24 than the quality of the TP30 in my opinion. The Dana is a very easy boat to steer and she will practically steer herself in most situations so Dave never has to work very hard and this must surely be the main reason why he is still working. That said, he has steered us bare poled before a gale mid Atlantic for 24 hrs and did an alright job.

The TP30 has an NMEA input so it can be made to steer to a waypoint but we always simply put the boat on a heading and press the red button. The controls are simple and the unit has coloured leds that light when you press a button. It also beeps so you know that the button has been pressed correctly. There are just 5 buttons to press for all the adjustments.

Dave can be used as a stand alone autopilot using his built in compass or you can fit a separate compass somewhere else on the boat. If you have wind instruments the unit can steer the boat by using the wind. There are also adjustments for gain and seastate.

There is an auto tack feature which when pressed tacks the boat through 100 degrees. Sadly this amount cannot be adjusted so when heading upwind I find that I have to head down 10 degrees or so before I press the tack button or the boat almost has the wind on the beam after I have tacked. It really is a shame that there is no simple way to adjust this to suit your boat’s best upwind angle.

It wasn’t cheap. At the time it cost about £450 which is a lot of money for a plastic tiller pilot but it does seem to work fairly well for most of the time. Basically the times it doesn’t want to work well are the times when if you took the helm you would have a hard time too. It’s quite powerful but not very fast nor is it predictive. It has to wait for the course to change before putting the helm over. To some degree the way you adjust the gain and sea state can help but the bottom line is that it has limitations.

No doubt a proper hydraulic under deck unit with separate compass and computers would be a much better way to steer the boat in more extreme conditions but as a compromise the TP30 isn’t bad. It is easy to fit. All I have to do is plug it in, drop the pin into the support and the other end snaps onto a pin on the tiller. It uses very little power and obviously the less it works the less power it will use but in any case I would be surprised if on Doolittle it takes more than 5 amps over 24 hrs which is brilliant.

Rather than drill a hole in my boat to fit it I simply added an Antenna mount bolted to the pushpit. It works very well.

A simple clamp on antenna mount is bolted to the stanchion and allows tillerpilot mounting without making holes in the boat. This has worked for over 13,000 miles so far.

Conclusion

If you have a modern boat that is easy to steer and light on the helm, the TP30 should work quite well.

It takes very little power and is quite powerful albeit rather slow to respond and move the helm.

It suffers a few design faults that can be easily sorted out. It also needs regular maintenance to keep it going.

It can be connected to NMEA, it can steer by separate compass or wind. There is a remote control as an option.

Don’t make it work hard and get hot and whatever you do, keep it away from water!

I had a TP20. It worked well on the open stretches of the French canals. It worked well for a while running downwind in F4-6. It steered all day and night on various passages of 200 miles plus when we motored.

As soon as the wind got up and I “really” needed it then it was hopeless. It was designed for boats up to 30 foot. Mine is 20 foot and tracks well.

It just couldn’t cope with hard work.

Still under guarantee it packed up and had to go back for repair.

I was in France and used the French dealers in Port Cogolin. It came back with glue all over the place (the glue they used to stick the light lenses in had melted the cover!). It was such a mess I took it back to the UK and sent it to Simrad UK who begrudgingly repaired it again under warranty.

Then it started just going off course suddenly and after that it just didn’t work at all.

I sent it back to Simrad in the UK again and the repair quote plus postage was almost as much as a new one. So I ditched it.

I just can’t bring myself to pay another £400-500 for another piece of crap like that. I cannot work out why they are so expensive. There’s nothing to them. What exactly is in there that’s so expensive? The nav software? the motor? the circuit board?

Ah I know! its the crappy rubber drive belt! They cost £300!

[…] One of the main problems with tiller pilots is that they are always situated right at the back of the boat and because the compass is inside the pilot it cannot react as quickly as a compass paced more forwards and at a lower level. It’s true that the TP30 can use a remote compass but that doesn’t disguise the fact that it is noisy and not very powerful. Read a review of the TP30 here […]