Previous Dana 24s were fitted with the Yanmar 2GM engines, now they are fitted with the 3YM 20. It’s basically a very good engine but not without issues. Considering that Yanmar have been in the marine engine business for almost 100 years it surprises me that these problems still exist.

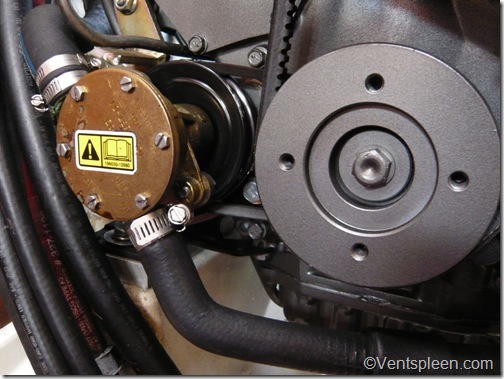

Yanmar have addressed some of the issues that plagued the old series such as turning round the sea water pump so that it faces forwards. before, just a simple thing like changing the impellor was made extremely difficult because you couldn’t see what you were doing. It now also has an O ring seal which certainly makes replacing the impellor easier. (see pic above)

Basically the engine is well made and reliable which is no doubt where Yanmar’s reputation has come from but there are far too many problems still.

Spare parts are very expensive and most often Yanmar dealers (especially in France) do not carry stock, even for the most basic of parts. If this is the case and you have to order the parts, expect a long wait, sometimes months long. If you’re stuck in a foreign marina while you wait for parts this will be an expensive concern.

Lets talk about the engines, starting with the fuel filter. Why does it have such a stupid system? What is wrong with a screw on cartridge? Oh no, Yanmar prefer to use a system that needs a special spanner that is not supplied in the tool kit. So if you want to get it off, a hammer and screwdriver is inevitable. I have witnessed Yanmar mechanics doing it like this! Yanmar do make a spanner but it has to be ordered specially and is a ring spanner, so to undo the fuel filter nut, the fuel lines must be removed from the filter body and the filter removed from the bracket. Clever stuff eh? The air bleed screw on the alloy filter housing is very small with coarse threads and in time is liable to strip it’s threads.

Even with the air filter removed it is still almost impossible to even see the oil filter, let alone get at it. Can you see it?

The oil filter is hidden on the side of the engine in the middle where it is practically impossible to get to. There is no lip behind the filter so there is no way to wrap a bag around the filter when removing it to catch the oil. It is not even possible to get a container or anything else under it. What this means is that when the filter is changed, old engine oil is spilled all down the engine and probably into the bilge of the boat and then out to sea. And Yanmar claim they are careful about the environment. This system is pathetic. Most other manufacturers fit the filter at the front of the engine where it is at least accessible or they mount it vertically.

Yanmar do not see fit to give you even a sump drain plug! So oil must be sucked out of the dip stick. Again, this is ridiculous. Why not supply the engine ready fitted with a small sump pump so it can be easily removed? Yanmar do offer a pump out kit that costs about £200. It consists of a pump and a piece of hose. None of the fittings needed are present, not even jubilee clips!! What is the point of that? The oil dip stick banjo has to be removed and machined in order to fit a special connector. Nice and easy. (not) thanks Yanmar! For a solution to this problem, read this post. Many other engine manufacturers offer a ready fitted pump to drain the oil.

Here is a picture of the modified sump banjo nut. As you can see there is no ordinary sump nut!

In their wisdom Yanmar do give you two places to put oil but neither are well placed. The one on the top seems ok but the other is on the side near the front. Why not put this at the front? Since most marine engines only have access at the front, this seems like an after thought.

The engine mounts may be flexible but they are very poorly made and hugely expensive (expect to pay about 800 Euros!) There is hardly any paint on them at all so they quickly rust, then they come unglued, then what is holding the engine to the boat? Not much. There is an Australian alternative that might be worth trying. They are made of plastic so can’t corrode.

Very poorly painted and liable to come unglued when rusty. For the price, they should be gold plated and come in a silk lined mahogany presentation case!

After just six months with my new engine, I noticed that the level in the expansion tank was falling. On inspection I discovered a leak from the heat exchanger. It seems that in an attempt to save money on manufacturing costs, Yanmar now press in the lower pipe on the heat exchanger which then leaks. Older engines had a pipe with threads so if it did start leaking at least the pipe could be removed and re sealed. Now, the only choice is to fit a whole new heat exchanger. Price about 2000€.

After many months Yanmar finally agreed to replace the exchanger which then started leaking again six months later. After many more months, lots of phone calls and emails, I finally got Yanmar to supply yet another exchanger. They claim that no one else has had this problem. ‘We’ve never heard that before’ they said. Well it seems odd that I had two exchangers with the same problem. In the end I got a mate to weld up the area where the leak happens and that was the end of that problem.

After just three years I started to have serious problems with the engine. After much head scratching I discovered that the exhaust riser was almost completely clogged with soot! Because my engine is fitted low in the boat, it need to have the exhaust adapted to be higher than the waterline. Yanmar supply a cast iron riser at a cost of over 500 Euros! but the design is frankly pathetic. It is a 40 year old design from an 8 hp engine. The internal diameter of the riser is tiny compared to the diameter of the rest of the system. What is the point of a 50mm exhaust hose when the riser has half that? It’s not really a surprise that the riser blocked up really.

This is a bronze alternative to the cast iron Yanmar one which is far too small and liable to clogging. Not to mention the increased back pressure and power drop it causes. If you have a cast iron Yanmar riser, check it annually for clogging. If your engine refuses to rev and starts to bilge out black smoke, suspect a clogged riser.

I spoke to Yanmar who pointed out that the riser should be checked every season for this. But I find this ridiculous. I agree that it can’t hurt to check these things regularly but every year? I have spoken to a lot of other owners of different engines and many marine engineers and none of them had ever had a similar problem. I solved the problem by fitting a bronze riser with a much larger inner diameter, made in Norway. Since then I have not had any problems.

If the riser is restricted then the engine is probably also not producing the correct power but the worst problem is when the exhaust gas cannot escape properly and all that carbon filled gas is forced back into the engine. If it gets into the oil it will act like sandpaper on all the bearing surfaces and slowly destroy the engine. It amazes me that Yanmar deem that riser to be suitable for the 3YM. If you have a riser fitted on your 3YM I suggest that you clean it every year or replace it with a larger diameter one.

After just 4 years the sea water pump started to leak very badly. On inspection I discovered that the entire shaft was ruined as were the bearings. There’s no point just buying new bits either. The bearings cannot be fitted to the shaft by mere mortals, you’ll need a special press. I bought a new shaft and bearings and it came to over 250 Euros! When you consider that the same parts for a Beta Marine engine of the same size is only 50 Euros you have to wonder. The pumps are made by Johnson and are not very good. I have spoken to a lot of people about this and it seems that these pumps are not up to the job. One dealer simply throws them away and fits a different make of pump. Some commercial users are replacing the pump every season because of wear. Considering how important cooling is for an engine it seems strange that Yanmar cannot come up with a better and more robust solution.

Why does Yanmar fit a separate belt to drive the water pump? (see first photo on this post) It’s like they built the engine and then thought, ‘Oh yeah, where shall we put the sea water pump?’ Other manufacturers drive the pump directly from the engine. Yanmar use a belt that cannot be replaced without first removing the alternator belt. Just what you want to do at sea when it’s rough. No doubt there is a reason why they do it this way but I have no idea what it is!

Every year it was something. I complained to Yanmar and after a marathon fight they finally agreed to change the engine. It took me almost a year to get the new engine. Trying to communicate with Yanmar is very difficult. Their website is awful and their contact form overly complicated. No one I spoke to was interested in hearing what I had to say. As far as they were concerned their engines are perfect as they are and they don’t need or want any feedback.

These were serious issues but there are plenty more lesser ones that are just as annoying. For example the engines are often painted after completion, obviously cheaper this way. Even the rubber pipes are covered in paint which of course cracks off and ends in the bilge and looks ugly.

On the subject of pipes, the large pipe that goes across the front of the engine is a special shaped hose so if it needs replacing you’ll have to buy it from Yanmar. Other more intelligent manufacturers use standard straight hose that can be easily and cheaply replaced, they also place it behind the alternator belt and not in front like Yanmar. A marine diesel engine should be easily repaired, perhaps even at sea. The more specialised parts fitted to an engine, the more unseaworthy it becomes.

If you want hot water from your Yanmar engine you’ll have to buy special parts again. There are two take-offs both have different threads. Why can’t Yanmar use standard BSP threads like everyone else? Needless to say, the price of these ‘special’ parts are hardly cheap and have to be ordered.

The one time that the engine would not start was when I discovered a wire had fallen off the starter motor. Unbelievably the wire that operates the starter is just a spade connector. This should be attached more permanently since when it falls off, the engine will not start! It’s stupid things like this that let down an otherwise good engine.

Sadly there’s more. The engine panel is very poorly made. It’s covered with a plastic sticker that soon comes unglued and looks terrible. When you consider how visible the engine panel is one has to wonder why Yanmar use such rubbish materials. Instruments are minimal with a rev counter and a few warning lights and an alarm. The hour meter is digital and incorporated into the rev counter. There is a stop button which operates an electric solenoid on the fuel injection pump.

Hour meter incorporated into the rev counter. There is no way to reset the hours if you do change the engine. Note the two dead fruit flies at the bottom. No idea how they got in there but there’s no getting them out!

The gearbox comes with a choice of forward ratios although the reverse gear is always 3.06 to 1 which can cause problems with some feathering props like the Kiwiprop.

The Yanmar key is a joke. Apart from the fact that all keys are exactly the same making the boat easy to steal, the key does not stay in the slot and falls out all the time. Also it is made of a cheap alloy so corrodes quickly.

Already corroding. Start any Yanmar engine with the same key.

If you want a workshop manual you’ll have to pay about 100€ for it. Most other manufacturers offer this as a free pdf download from their website.

The air filter is simply a piece of foam. A more effective filter would be a cartridge. Probably quieter too. The paint on the filter assembly is feeble and soon rusts.

Fuel economy is good for an 800cc three cylinder engine. We use about a litre and a half an hour at least at lower revs. Crank it up and you can double the consumption! The exhaust is always very clean. Sometimes there is a little puff of smoke on start up but that goes instantly. The transom does get a small amount of exhaust soot on it but it’s not terrible. In any case, exhaust soot is easy removed with Clean Boat.

It’s quite smooth but then it does have three cylinders. It always starts well,, even without the pre heat.

All in all these engines could be massively improved. The basic engine seems very good but they spoil it with idiotic and unseaworthy attachments and accessories. I must confess to be very disappointed. Maybe I was unlucky with the first engine, after all it was one of the very first in production. Maybe the later models have been improved. It’s too early to tell whether the new engine will be any better than the last one.

The bottom line is that I will not buy another Yanmar engine. Not after experiencing their awful customer service and not unless they offer their customers a bit more for their money. My next engine will probably be a Beta or a Nanni. These are based on the Kubota engine which is well proven world wide and the parts are much cheaper. Both engines offer easier servicing, built in oil sump pumps and cheaper parts.

I got a brand new Yanmar 20 HP and within the first 20 hours, the plug from the engine panel that connects to the solenoid on the engine came unplugged (I think the “spade” plug that the connection slides in and out of) and the engine wouldn’t stop running. I’m glad that someone was around to help me then for sure! The access to the engine in my old 79 Cal 31′ is pretty good with the cavernous area accessible via the port and starboard cockpit lazarettes-besides the large standard access from the cabin.

Thanks for sharing your info as it sure may come in help with any trouble in the future.

What’re the advantages and disadvantages of the diesel two stroke engine?